Inspection News

Ensuring Safety in Lithium-ion Batteries: A Comprehensive Checklist and International Safety Standards

Lithium-ion batteries are widely used in various applications, including electric vehicles (EVs), portable electronics, and renewable energy storage systems. While they offer high energy density, strong performance, and extended lifecycle, ensuring their operational safety remains a top priority. This comprehensive guide by VIS Quality Control provides a detailed safety checklist and highlights international standards designed to prevent major hazards such as thermal runaway, fires, and explosions.

Electrode Material Selection

The selection of electrode materials has a direct impact on overall battery safety. Manufacturers should prioritize materials with high thermal stability and low reactivity to reduce the likelihood of catastrophic failure. Approaches such as using thermally stable electrolytes, optimizing chemical formulations, and incorporating flame-retardant additives can significantly minimize the risk of thermal runaway.

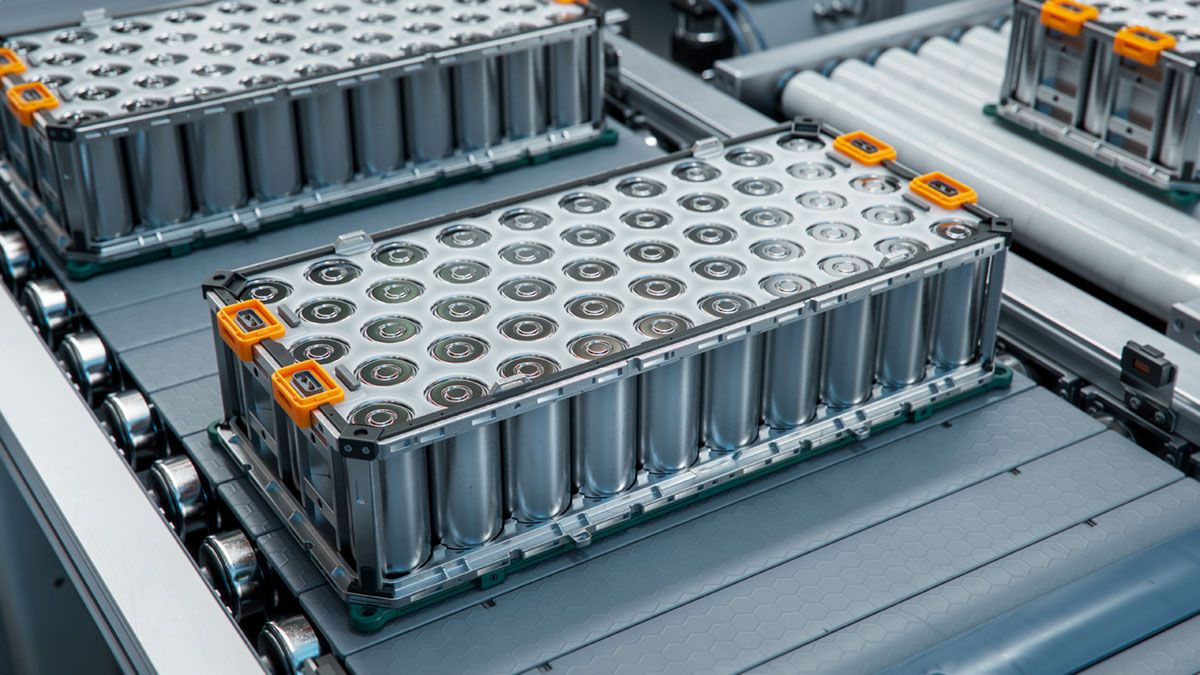

Cell Design and Manufacturing

Proper cell design and strict manufacturing protocols are fundamental to ensuring lithium-ion battery safety. The following components should be carefully considered and controlled:

- Separator Design: High-quality separators with strong thermal stability and puncture resistance are essential to preventing internal short circuits that can trigger thermal runaway.

- Electrode Coating Integrity: Uniform electrode coating helps eliminate localized hotspots, improving long-term stability and reducing degradation.

- Venting Mechanisms: Incorporating pressure relief vents or engineered venting mechanisms allows excess gas to be safely released during abnormal operating conditions, preventing explosions.

- Quality Control: Comprehensive QC systems, including multi-stage inspections, traceability programs, and robust testing procedures, ensure consistent production quality and early detection of manufacturing defects.

State-of-Charge (SOC) and Voltage Control

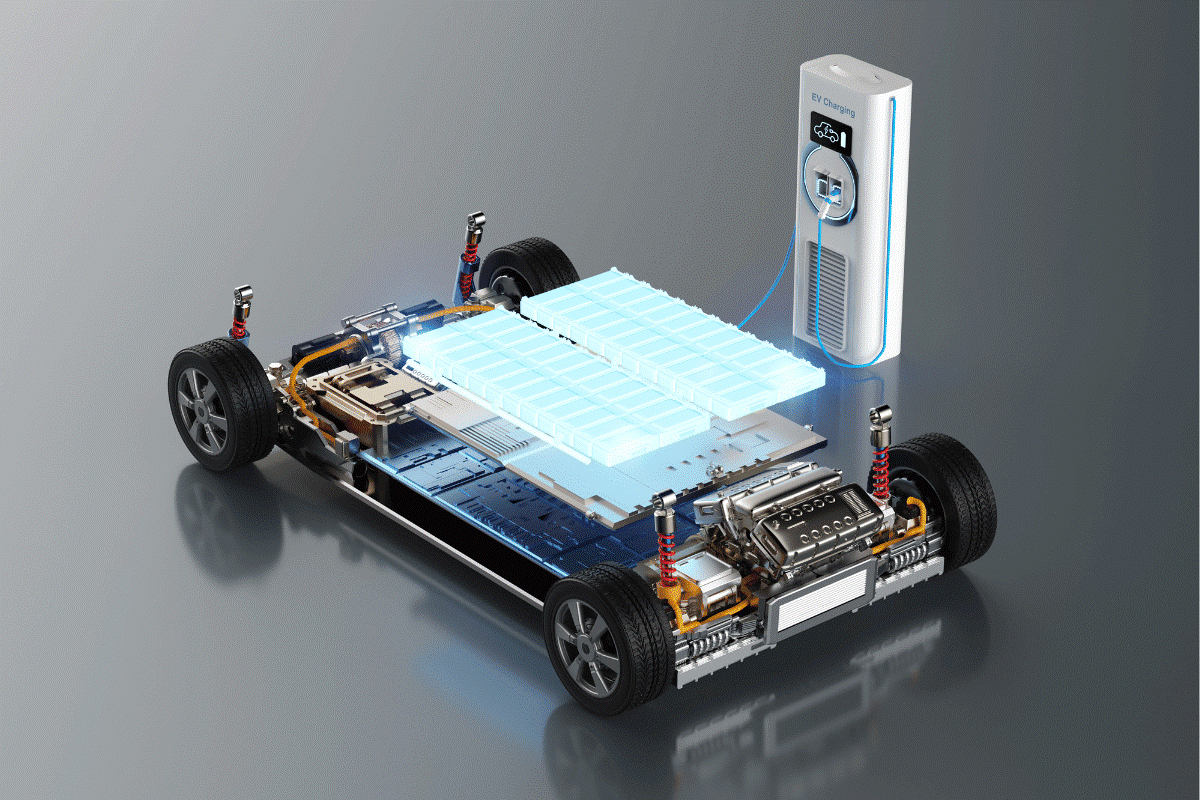

Effective control of the battery’s SOC and voltage is vital for safe operation. Overcharging or deep discharging can destabilize the chemical structure of the cell, increasing the risk of fire or explosion. Advanced battery management systems (BMS) should be utilized to continuously monitor and regulate SOC and voltage, keeping them within safe operational thresholds and creating safeguards against abnormal electrical conditions.

Temperature Management

Temperature is one of the most critical factors influencing lithium-ion battery performance and safety. Excessive heat buildup during use, charging, or environmental exposure can initiate thermal runaway. Effective thermal control strategies include:

- Thermal Management Systems: Integrating liquid cooling, air cooling, or hybrid thermal management systems helps maintain optimal cell temperatures and prevents overheating during peak load conditions.

- Temperature Sensors: Internal sensors installed throughout the battery pack enable real-time monitoring, early warning of thermal anomalies, and automatic activation of protective measures.

Charging Infrastructure

Charging infrastructure must comply with industry safety requirements to minimize risks during the charging process. Important considerations include:

- Overcurrent and Overvoltage Protection: Integrating safeguards to prevent excessive current flow or overvoltage events during charging cycles.

- Ground Fault Protection: Ensuring proper grounding and incorporating ground-fault protective devices to reduce electrical shock and fire hazards.

- Charging Station Inspections: Performing routine inspections, maintenance, and safety audits to ensure all charging equipment remains reliable and free from critical defects.

Transportation and Handling

Proper handling and transportation procedures are essential to preventing accidents involving lithium-ion batteries during storage or transit. Key practices include:

- Packaging Standards: Complying with globally recognized packaging regulations such as UN38.3 to ensure safe handling and transit of lithium-ion batteries.

- Impact and Vibration Resistance: Ensuring battery packs are protected against shock, impact, and vibration during transportation in order to prevent internal damage.

- Training and Awareness: Providing comprehensive training programs for logistics teams and handlers to reinforce safe handling protocols and emergency response procedures.

International Safety Standards

Multiple international standards and certifications guide the safe production, use, and transportation of lithium-ion batteries. These include:

- UN Manual of Tests and Criteria: Outlines testing procedures related to transportation safety, including thermal abuse tests, mechanical shock tests, and external short-circuit evaluations.

- IEC 62133: Defines safety and testing requirements for portable sealed secondary lithium cells and batteries.

- ISO 12405: Provides guidelines for the safe design, testing, and use of lithium-ion traction batteries in electric vehicles.

- UL 2580: A widely adopted safety standard for lithium-ion battery packs implemented in electric vehicles.

Conclusion

Ensuring the safety of lithium-ion batteries is essential to preventing severe incidents such as thermal runaway, fires, and explosions. A thorough safety framework must include careful electrode material selection, optimized cell design, strict SOC and voltage management, robust thermal control systems, safe charging infrastructure, and proper transportation and handling procedures. Adherence to well-established international standards provides manufacturers, operators, and end users with confidence in the reliability and safety of lithium-ion batteries across multiple applications.

If you need expert consultation or support related to vehicle inspection services, please feel free to contact VIS Quality Control for professional assistance.