Have you ever gotten a report from quality inspectors for your product and chose to send or hold an order that didn’t match the main result in the report?

You’ve likely encountered this situation if you’ve used a team to check your product’s quality before sending it out. It’s common, especially when making things in places like China or Southeast Asia, where a ton of production happens. You may send out products that could have done better on the check or ask for changes on products that passed the check.

A reliable inspection report gives detailed information and insight into your goods’ quality, status and condition. But the inspection result needs to tell you whether or not you should accept the order. And if you do not define inspection criteria and scope adequately before inspection, the inspection result may not reflect your standards accurately. In this article, we’ll walk you through how QC inspectors come to their conclusions, understand them, and show you how to make smart choices when deciding whether to approve or decline an order.

How QC Inspectors Reach a QC Inspection Result

An inspection report is like a summary of what an inspector sees when they visit your order’s location. The QC team compares your products to the standards you’ve set using materials you’ve given them, like the purchase order, drawings, checklists, and other papers. They might also test your product on-site to ensure it works well, performs correctly, and is safe. If anything doesn’t match what you wanted, they write it down in the report.

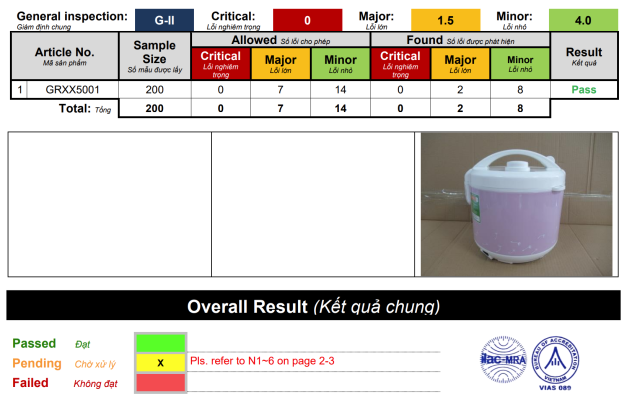

Another important aspect of inspection results is the “Acceptable Quality Limits” (AQL) outcome. During an inspection, the QC team often uses the AQL standard to judge the overall quality of a whole batch of items. They do this by checking a random group from the batch. When deciding on the AQLs for your order, you need to find a balance between how much it costs and how well you can understand the quality of your order.

Clear expectations help you ensure accurate inspection results.

You must accurately and readily provide all reference materials and inspection criteria to yourself, the QC team and your supplier. This is true whether you have hired a third-party or full-time inspector or are sending someone from your company to inspect. Even if you depend on the factory’s QC team for the inspection, giving them all your needs ahead of time will ensure they know what you want. This way, they can meet your expectations better.

It’s best if you lay out the rules for the inspection well before the inspector shows up at the factory, and it’s even better if you do this before the factory starts making a lot of stuff. When you team up with your supplier and the QC folks, and you all decide on the inspection criteria, it ensures everyone understands what the final products need to meet. Many experienced importers use a checklist to make this info clear and easy to follow.

How to Interpret Your Product Inspection Results

Most times, product inspections end up with one of these three outcomes:

- “Pass” happens when the product quality meets the set standards, has cleared any needed on-site tests, and meets other requirements or rules.

- “Fail”: If too many problems or things don’t match the standards, it’s a failure. Also, failing can occur if it fails to pass one or more important tests or if it doesn’t meet a very important rule.

- “Pending”: In this case, the product quality is all right according to the set standards and has passed the on-site tests. Everything looks good, but there’s something extra that the inspector noticed, something that needed to be added to the documents or the rules. They want to talk to the person who ordered the inspection about it.

Inspectors might use various words to tell the results, like saying “accept” instead of “pass,” or “hold” instead of “fail,” and they might use special terms related to AQL. However, usually, these are the main things that describe the basic results.

Usually, when inspections happen often, and the rules are clear, you can easily decide by looking at a pass or fail result. But sometimes, there are exceptions. You may do something different from what the inspection result suggests, like accepting or rejecting an order.

When You Might Reject a Passing QC Inspection Result

The QC experts usually use your rules to check the product during the inspection. When the result is a pass, you can usually send out the order. However, sometimes you might say no to shipping, even if the result is a pass. This choice often means that you should have put important details in the rules for that inspection.

Here’s an example: Imagine you buy 5,000 felt pens from a supplier in Shanghai. But here’s the catch – you forgot to mention the ink color in your inspection rules. The inspector checks a sample of 200 pens and sees that they are packed well and meet the rules for how they look and work. According to the rules, this is a “pass.” But when you read the report, you see that the pens have blue ink instead of the black ink you wanted.

This thing doesn’t usually happen because you would have probably told your QC team in China about something so important. Still, this example shows how leaving out important details can mess up the inspection results. It can also cause headaches for the factory managers and workers who have to fix or replace things, even though the inspection said everything was fine.

When You Might Accept a Failing Product Inspection Result

An importer can still say yes to an order even if the inspection says it didn’t do well. This usually happens when the inspection rules aren’t quite right, just like saying no to something that passed the inspection. You might also agree to an order that didn’t pass because of small issues you don’t think are a big deal. These are called “minor” AQL defects. You could also agree to an order that didn’t pass if you need to ship the stuff quickly. But you can stop this from happening by scheduling the inspection well before you plan to send out the goods.

How to Handle a Pending Inspection Result

When the inspection results are marked as “pending,” the inspector is being extra careful because they’ve noticed some possible problems that the usual inspection rules don’t cover. For instance, the factory might not let the inspectors do a certain test, or the inspectors could measure the product and find it doesn’t match the size rules, even if there are no specific size limits. These situations mean the inspector must talk to you before asking if it’s a pass or fail.

If you feel the things pointed out in a pending report aren’t serious, you might say sending out the order is okay. On the flip side, if the problems need more checking or fixing from the factory, you might say no to the order.

If a pending result or your decision to ship the order doesn’t match the result, talk to your inspection team. Tell them how to think about these things better in future inspections so they can avoid similar issues. And if the rules change between planning the inspection and getting the results, tell your supplier and the inspector immediately to make sure everything is clear.

Whenever you see a pending inspection result or your choice to ship the order doesn’t match the result, talk to your inspection team. Please share your thoughts on how they can think about these things better next time to prevent similar issues. Also, if the rules change from when you set up the inspection to when you get the results, tell your supplier and the inspector immediately. This helps make things clear for everyone.

Using Inspection Reports to Your Advantage

Why does inspection matter in some reports? The real value of these reports lies in their transparency, enabling you to decide whether to accept or decline an order. Additionally, your product’s manufacturing factory can benefit from inspectors uncovering issues their quality control might have missed.

Empowering Importers with Informed Decisions

To make wise choices about shipping, it’s crucial to thoroughly review the entire inspection report, not just the summary on the first page. This comprehensive information sheds light on your product’s status at the factory. By paying attention to these details, you can prevent the hassle of shipping products that don’t meet your expectations. This can save you from dealing with unsellable items or costly rework after the goods have left the factory.

Taking Control and Making Decisions

After the inspection, it’s up to you as the importer to call the shots. QC inspectors act as your eyes and ears in the factory, but only you have the authority to guide your supplier on what to do next. While inspectors don’t usually work with the factory to fix issues, you can collaborate with the supplier to determine the necessary steps, such as reworking, replacing units, and other solutions before shipping.

Benefitting Factories Through Inspection

Inspection isn’t solely about pointing fingers at suppliers’ mistakes. Even though some suppliers might resist inspections, they can gain from them. External inspections help suppliers improve their production and internal quality control processes. When issues arise, inspection reports pinpoint areas for improvement, allowing suppliers to enhance their service to customers.

Conclusion: How to Use QC Inspection Results for Shipping Decisions

Inspection reports give importers a complete picture of product quality, especially when they establish important inspection criteria ahead of time. They provide the details necessary for educated decision-making. But a “fail” or “pass” result alone is not always an immediate guarantee that you should ship an order.

When shipping your order, your QC inspection results can clear up a lot of uncertainty. Yet, the final responsibility lies in carefully studying the results and communicating with your supplier about what to do next. This approach ensures you maximize the benefits of QC inspections for your products.

Related Posts