Inspection News

How ANSI/ASQ Z1.4 Can Help You Achieve High-Quality Products and Customer Satisfaction

When it comes to ensuring the quality of consumer products, importers and quality control professionals turn to ANSI/ASQ Z1.4, the industry standard for AQL (Acceptable Quality Limit) sampling. However, due to its perceived complexity, some business professionals shy away from utilizing this powerful tool. In reality, anyone can quickly grasp and apply the ANSI/ASQ Z1.4 table to enhance product inspections and monitor quality effectively.

5 Key Components of ANSI/ASQ Z1.4

The ANSI/ASQ Z1.4 table, developed by the American National Standards Institute (ANSI) and the American Society for Quality (ASQ), comprises five main components that dictate the AQL sampling plan for inspections.

Lot Size

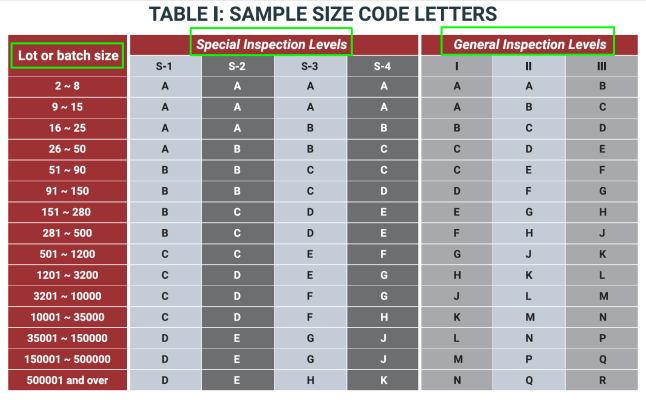

The lot size represents the total order quantity, which is the starting point for using the ANSI/ASQ Z1.4 table. Select the appropriate lot size range that corresponds to your order quantity.

Inspection Level

This part of the table is categorized into “general inspection levels” and “special inspection levels.” The inspection level chosen is a critical factor in determining the scope of the product inspection. Consider your product quality standards, customer expectations, and time and budget constraints when making this decision.

General Inspection Levels: QC professionals use general inspection levels for checks performed on the main sample size, which includes all SKUs in the order. These checks involve visually inspecting the product for defects and conducting on-site tests.

Special Inspection Levels: Special inspection levels are used for specific product tests that should only be conducted on a smaller sample of units. These tests may be destructive, expensive, or yield similar results across all units.

Sample Size and Code Letters

Based on the chosen inspection level and lot size, the ANSI/ASQ Z1.4 table provides a corresponding code letter representing the sample size. For instance, “H” corresponds to a sample size of 50 units. Some sample sizes may require adjustment based on your AQL tolerance.

Image 1. Lot size, Inspection Levels and Code Letters from Table 1 of AQL Sampling Plan

Acceptable Quality Levels (AQL)

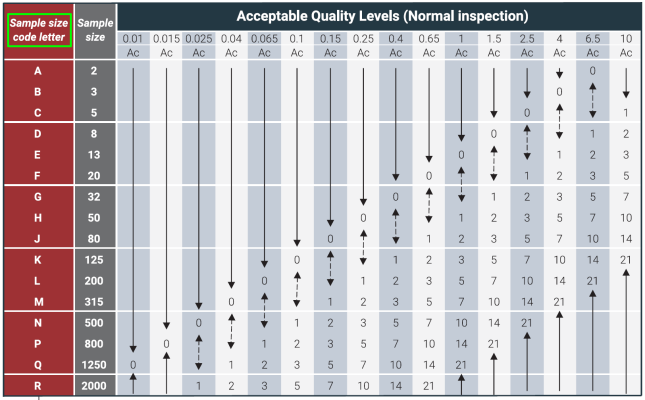

AQLs range from 0 to 15 percent or more, representing the tolerance for defects. Different AQLs are typically set for critical, major, and minor defects. Consider various factors, such as supplier expectations, inspection budget, and product value, when determining the best AQL for your circumstances.

Acceptance and Rejection Points

Each AQL for defect types corresponds to specific acceptance and rejection points. These points determine the maximum number of acceptable defects and the minimum number required to reject the order.

Practical Benefits of Using ANSI/ASQ Z1.4

Embracing ANSI/ASQ Z1.4 brings numerous benefits for business professionals engaged in importing and quality control:

Enhanced Quality Control

By utilizing the ANSI/ASQ Z1.4 table, businesses can ensure a reasonable representation of their product’s overall quality. This helps detect potential issues early and prevent substandard goods shipment.

Cost-Effective Inspections

With clear guidelines for sample sizes and AQLs, businesses can optimize inspection efforts and minimize costs. Choosing appropriate inspection levels and AQLs tailored to specific product types and customer expectations ensures efficient inspections without compromising quality.

Supplier Collaboration

Agreement on quality standards and AQLs early in the process fosters strong supplier collaboration. Avoiding disputes post-inspection allows for smoother operations and reliable product quality.

Conclusion: How ANSI/ASQ Z1.4 Can Help You Achieve High-Quality Products and Customer Satisfaction

Understanding and applying ANSI/ASQ Z1.4 can be manageable for business professionals. This industry-standard AQL sampling method empowers importers and QC professionals to ensure the quality of consumer products efficiently and effectively. By leveraging the ANSI/ASQ Z1.4 table, businesses can confidently choose the right sampling plan and AQL that aligns with their inspection needs and budget, ultimately delivering high-quality products to customers.

Read our next article on how to read the AQL Sampling Plan with practical example.