Inspection News

How to Read AQL Sampling Plan

What is AQL Sampling Plan?

- How many units should I inspect for an inspection?

- How many defective units are allowable before the inspection fails?

How to Read AQL Sampling Plan

To read the sampling plan, you need to understand some basic terms below.

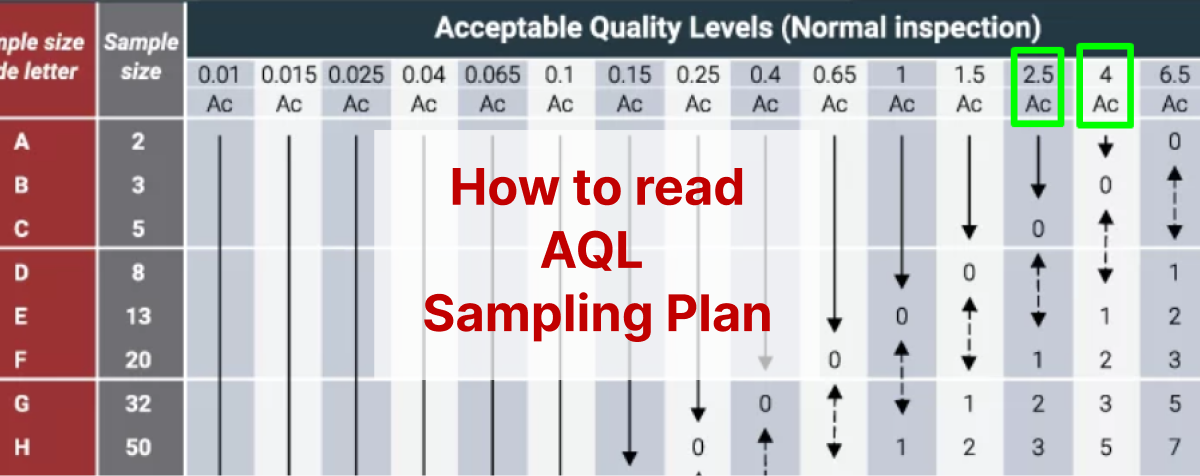

2 Tables in Sampling Plan

There are 2 tables in the AQL Sampling Plan: Table 1 for sample size code letters and Table 2 for single sampling plans for General inspection.

Lot size, inspection level and AQL level

Lot size is the total number of units in your shipment.

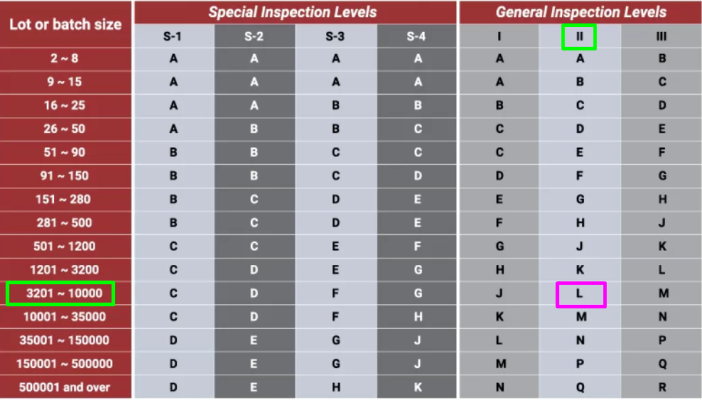

Inspection level will determine the sample size. The inspection level, which determines the sample size. There are three general inspection levels (I, II, III) and four special inspection levels (S-1, S-2, S-3, S-4). The higher the level, the larger the sample size. The inspector usually use Level II for most situations.

- Step 1: Find the sample size code letter from Table 1 by locating the intersection of your lot size and inspection level.

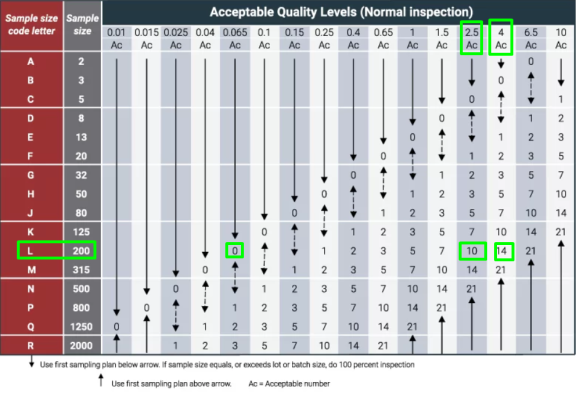

- Step 2: Find the sample size, acceptance point, and rejection point from Table 2 by locating the row of your sample size code letter and the column of your AQL level.

- Step 3: Inspect the sample size randomly selected from your lot and count the number of defective units according to their types.

- Step 4: Compare the number of defective units with the acceptance and rejection points. If the number of defective units is equal to or less than the acceptance point, the lot passes the inspection. If the number of defective units is equal to or greater than the rejection point, the lot fails. If the number of defective units is between the acceptance and rejection points, use your discretion to decide.

- Step 1: From Table 1, find the sample size code letter by locating the intersection of your lot size (4,000) and inspection level (II). The code letter is L

- Step 2: From Table 2, find the sample size, acceptance point, and rejection point by locating the row of your code letter (L) and the column of your AQL level (0 for critical defects, 2.5 for major defects, and 4.0 for minor defects): The sample size is 200 units, the acceptance point is 0 for critical defects, 10 for major defects, and 14 for minor defects. The rejection point is 1 for critical defects, 11 for major defects, and 15 for minor defects.

- Step 3: Inspect 200 units randomly selected from your lot and count the number of defective units according to their types. Let’s say you find 0 critical defects, 8 major defects, and 12 minor defects.

- Step 4: Compare the number of defective units with the acceptance and rejection points. For critical defects, since 0 is equal to or less than 0 (the acceptance point), the lot passes. For major defects, since 8 is less than 11 (the rejection point), the lot passes. For minor defects, since 12 is less than 15 (the rejection point), the lot passes. Therefore, the lot passes the inspection.

Some Important Things to Understand About AQL Sampling Plan

- AQL sampling plan does not guarantee that your shipment will have zero defects. It only gives you statistical confidence that the proportion of defective units in your lot is within an acceptable range. There is always a risk of accepting a bad lot or rejecting a good lot by chance.

- AQL sampling plan assumes that your lot is homogeneous and randomly mixed. If your lot is not homogeneous or randomly mixed, the sampling results may not be representative of the whole lot.

- AQL sampling plan requires you to define what constitutes a defect and classify them into critical, major, and minor categories. This may not be easy or objective, as different buyers may have different expectations and tolerances for quality.

- AQL sampling plan does not tell you how to select the sample units from your lot. You need to use a random or systematic method to ensure that every unit has an equal chance of being selected. You also need to consider how many cartons or packages to sample from and how to distribute the sample units among them.

- AQL sampling plan does not tell you how to inspect the sample units or what methods or tools to use. You need to follow the product specifications and inspection criteria provided by your buyer or supplier. You also need to ensure that the inspection methods and tools are reliable, accurate, and consistent.

Conclusion: AQL sampling plan

AQL is still a critical quality control tool that helps ensure that the product meets the specified quality level and requirements, but you need to understand its limitations and use it in the way that meets your expectation. If you need more help or guidance on how to use AQL sampling plan for your product inspection, you can contact us at VIS Quality Control. We are a professional inspection company with many years of experience in helping importers ensure their product quality and compliance. Contact us today.