Conducting an inspection will ensure product quality. That’s why you may need a QC team to check the products before shipping, but how do you know they are professional? One thing to check is looking at the inspection tools your inspectors use. The right tools can help them measure, test, and evaluate your products accurately and efficiently. They can also help them detect defects early, improve productivity, and ensure accuracy. This guide will show you essential tools for every product inspection.

Measuring Inspection Tools

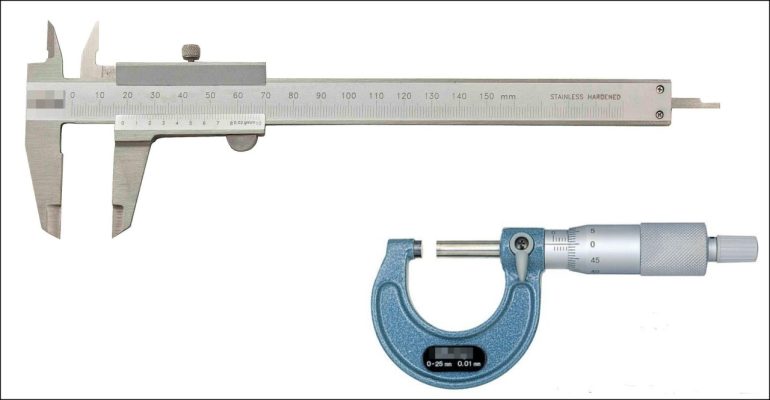

Measuring tools help you find out the exact size of your products. For example, how long, wide, high, round, or thick they are. Some industries need to be precise and accurate when making or building things. They use measuring tools for this. Some measuring tools are calipers, micrometers, rulers, scales, etc.

- Calipers help you measure different dimensions of an object by using two parts that can move along a scale. For example, they measure how wide or deep an object is by opening or closing the two parts around it.

- Micrometers help you measure very small or large dimensions of an object with high accuracy by using a part that can spin through a sleeve with threads. For example, they measure how thick or round an object is by turning the part until it touches it.

- Rulers help you measure the length of an object by using a straight edge with marks. For example, you can measure an object’s length by placing it along the edge and reading the mark where it ends.

- Scales help you measure the weight of an object by using a device that shows how much force the object puts on it. For example, you can measure an object’s weight by putting it on the device and reading the number it shows.

Detection Inspection Tools

Detection tools help you check if your products meet predetermined standards. For example, if they have the right size, shape, or features. Some industries need to have the same and consistent products. They use detection tools for this. Some detection tools are gauges, probes, barcode scanners, etc.

- Gauges help you measure specific dimensions or shapes of an object by using a template that fits or does not fit the object. For example, they measure if an object has the right size or shape by putting the template over it.

- Probes help you measure specific features or locations of an object by using a tip that touches or does not touch the object. For example, they measure if an object has a hole or a bump by putting the tip on it.

- Barcode scanners help you verify product and distribution information using a device that reads codes on labels or packages. For example, they verify if an object has the right code by scanning it with the device.

Visual Inspection Tools

Visual tools help you spot flaws in your products’ surfaces and designs using optical devices or systems. For example, if they have scratches, stains, or cracks. Some industries need to have good-looking and functional products. They use visual tools for this. Visual tools include vision systems, cameras, magnifiers, microscopes, Pantone swatches, etc.

- Vision systems help you take pictures of an object using a camera or a scanner and check them using software or algorithms. For example, they check if an object has defects by capturing and analyzing its images.

- Cameras help you take pictures or videos of an object using a lens and a sensor and show them on a screen or a monitor. For example, they show an object’s appearance by capturing and displaying its images or videos.

- Magnifiers help you see small details of an object by using a device that makes them look bigger. For example, they show you how an object’s surface looks by enlarging its features.

- Microscopes help you see very small details of an object by using a device that uses light or electrons to make them visible. For example, they show you how an object’s structure looks like by magnifying its parts.

- Pantone swatches help you compare the colours of an object by using a set of colour codes that are standardized and known worldwide. For example, they compare if an object has the right colour by matching it with the codes.

Documentation Inspection Tools

Documentation tools help you record and report your inspection findings. They are important for showing you what happened during the inspection and what actions to take next. Some documentation tools are cameras (again), defect stickers, inspection reports, etc.

- Cameras help you document product defects and other issues by taking pictures or videos of them. For example, they document how severe a defect is by capturing its image or video.

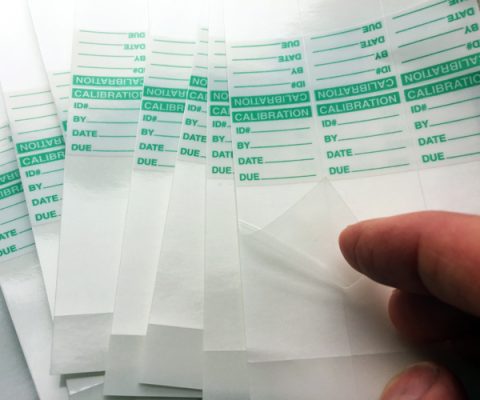

- Defect stickers help you mark defective units and point to specific defects by using labels with marks or measurements. For example, they mark which unit has a defect and where it is by sticking the label on it.

- Inspection reports help you summarize and communicate your inspection findings using documents with text, numbers, photos, etc. For example, by writing them in the document, they summarize how many defects were found and what types they were.

Conclusion: The Essential Inspection Tools and Why You Need Them

Inspection tools are essential for quality control in any industry. By understanding their types, benefits, and functions, you can ensure your inspection company uses the right tools for your products. To start your quality control journey with the best inspection tools, contact our team at for a free consultation.

Related Posts